Graphene coating

Graphene coating is a type of coating with high anti-corrosion ability obtained by adding graphene powder to solvent based coatings and uniformly dispersing them. This coating utilizes the excellent properties of graphene, such as high mechanical strength, conductivity, and barrier effect, to enhance the performance of the coating.

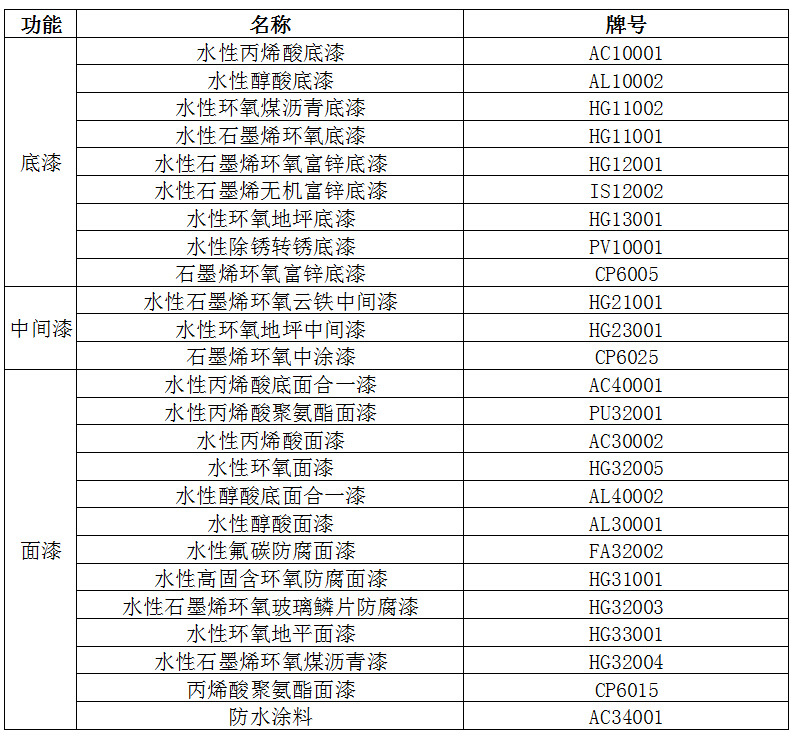

Product Classification:

Key words:

Share

Related Products

The SAL-O4 is based on the array of carbon nanotubes as the main material, NMP as the solvent. The product uses a new array of carbon nanotubes, diameter 4-11nm, average 7nm, purification process using high temperature purification. The slurry itself has the characteristics of very low metal impurity content, good fluidity and easy dispersion. Compared with the pure array carbon nanotube slurry, this product can significantly improve the rate performance and cycle performance of lithium ion batteries.

Product Features

1. Using a new array of carbon nanotubes, smaller diameter, better conductivity;

2. Very low metal impurity content;

3. High fluidity, viscosity less than 2000mpa · s (measured by rheometer 101/s);

4. Compared with ordinary array carbon nanotubes, the cycle performance and rate performance of the product can be significantly improved.

product morphology

Technical parameters

Use recommendations

It is recommended to use in NCM and LCO systems.

Packing method

Available in 25kg, 200kg or 1000kg packages.

The NFLR-O5 is based on iron-based wound carbon nanotubes as the core and NMP as the solvent. The product uses winding carbon nanotubes, diameter 10-25nm, average 20nm, purification process using acid washing purification, part of the carbon tube is not purified. The slurry has the characteristics of high cost performance, good fluidity and easy dispersion.

Product Features

1. Good conductivity, high cost performance;

2. Good liquidity and easy dispersion.

product morphology

Technical parameters

Use recommendations

It is recommended to use in NCM and LCO systems.

Packing method

Available in 25kg, 200kg or 1000kg packages.

GSLF-O10 is a conductive carbon black, carbon nanotubes and graphene composite conductive paste, NMP as solvent. Multi-conductive agent compound, build point-point, electric-line, point-surface multi-level conductive channel, with the minimum content of conductive components to play the best conductive effect, reduce the amount of conductive agent, improve energy density. At the same time, this product is a high solid content product with high cost performance advantages, which can solve performance problems for customers while reducing cost pressure.

Product Features

1. Multi-conductive agent composite, long-range conductivity and short-range conductivity, better conductivity;

2. High solid content, low cost, high cost performance;

3. Improve the battery charge and discharge rate and cycle performance, improve energy density;

4. Improve safety performance.

product morphology

Technical parameters

Use recommendations

Recommended for use in the LFP system.

Packing method

Available in 25kg, 200kg or 1000kg packages.

The GNLN-O5 is based on the nickel series coarse carbon nanotubes as the core, NMP as the solvent, adding a certain amount of graphene composite conductive paste. The addition of the appropriate proportion of graphene increases the flexibility of the pole, the high thermal conductivity of graphene, improves the heat transfer in the lithium-ion battery, and improves the safety performance. At the same time, the use of carbon nanotubes and graphene excellent electrical conductivity, can be in the whole material system to form efficient line surface contact, constitute a three-dimensional conductive network, can effectively reduce the battery internal resistance, improve the battery charge and discharge rate and cycle performance.

Product Features

1. Production of graphene by mechanical stripping method, high conductivity;

2. Reduce the amount of conductive agent and binder used, improve the battery density;

3. The slurry has stable viscosity, good leveling, easy dispersion and easy coating;

4. Improve the battery charge and discharge rate and cycle performance;

5. Improve safety performance.

product morphology

Technical parameters

Use recommendations

Recommended for use in the LFP system.

Packing method

Available in 25kg, 200kg or 1000kg packages.

Related Products

Message consultation

Our staff will contact you within 24 hours (working days). If you need any other services, please call the service hotline:86-451-88118909