HAL-O4 conductive paste

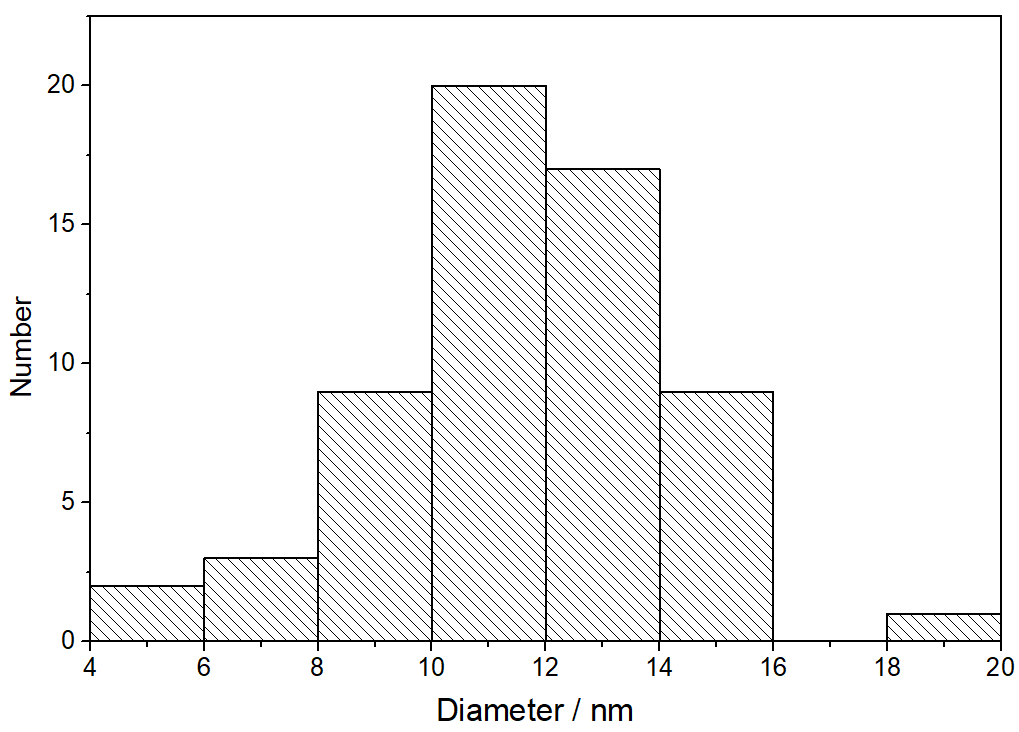

The HAL-O4 is based on the array of carbon nanotubes as the core, NMP as the solvent. The product uses array carbon nanotubes, diameter 4-16nm, average 11nm, purification process using acid washing purification compound high temperature purification array carbon nanotubes. The slurry has the characteristics of relatively low metal impurity content, good fluidity and easy dispersion. Compared with the traditional pure carbon nanotube slurry, the product can significantly improve the rate performance and cycle performance of lithium ion batteries. Product Features 1. Using array carbon nanotubes, the diameter of the tube is relatively smaller, and the conductivity of carbon nanotubes is better by pickling purification process; 2. Metal impurities are relatively low and cost-effective; 3. Compared with traditional carbon nanotubes, it can significantly improve the cycle performance and rate performance of lithium-ion batteries. product morphology Technical parameters Product Name Appearance Solid content Content of conductive agent Metal content of main impurities Pipe diameter HAL-O4 Black paste 5.0±0.2% 4.0±0.15% Fe≤10ppm Co≤1ppm 4-16nm Use recommendations Recommended for use in the LFP system. Packing method Available in 25kg, 200kg or 1000kg packages.

Product Classification:

Key words:

Share

Details

Product Introduction

The HAL-O4 is based on the array of carbon nanotubes as the core, NMP as the solvent. The product uses array carbon nanotubes, diameter 4-16nm, average 11nm, purification process using acid washing purification compound high temperature purification array carbon nanotubes. The slurry has the characteristics of relatively low metal impurity content, good fluidity and easy dispersion. Compared with the traditional pure carbon nanotube slurry, the product can significantly improve the rate performance and cycle performance of lithium ion batteries.

Product Features

1. Using array carbon nanotubes, the diameter of the tube is relatively smaller, and the conductivity of carbon nanotubes is better by pickling purification process;

2. Metal impurities are relatively low and cost-effective;

3. Compared with traditional carbon nanotubes, it can significantly improve the cycle performance and rate performance of lithium-ion batteries.

product morphology

Technical parameters

Use recommendations

Recommended for use in the LFP system.

Packing method

Available in 25kg, 200kg or 1000kg packages.

Key words:

Related Products

Related Products

Message consultation