NNL-HV3 conductive paste

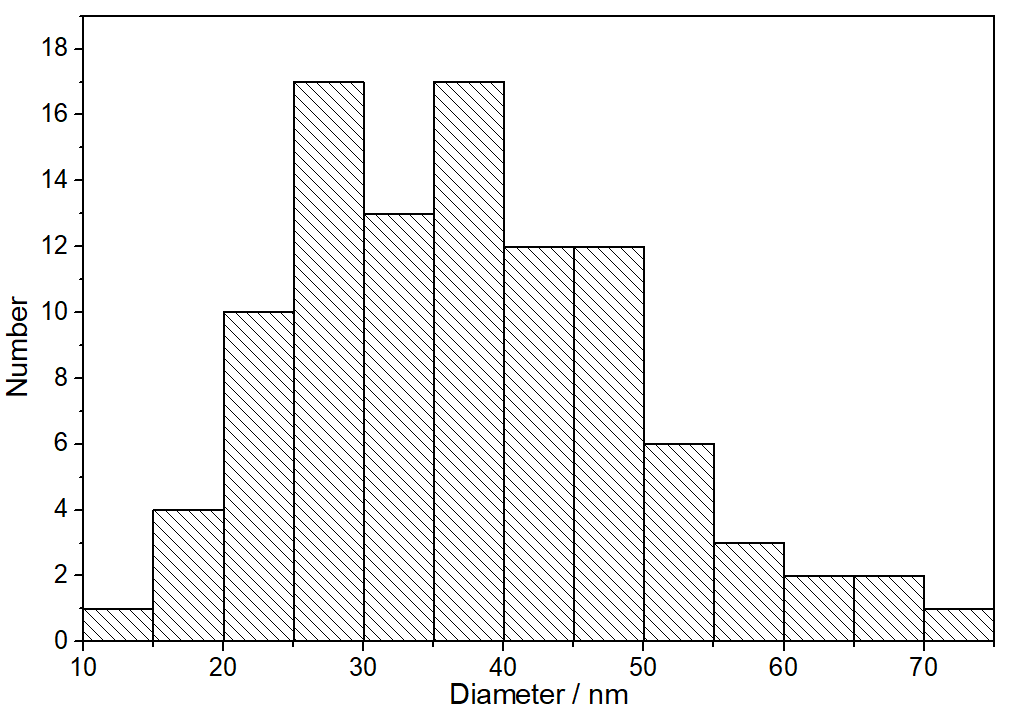

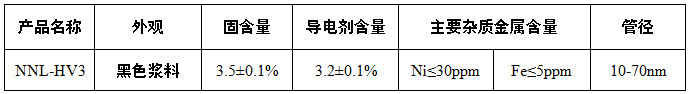

NNL-HV3 is easy to disperse carbon nanotubes as the main material, NMP as solvent. The product uses easily dispersed carbon nanotubes, diameter 10-70nm, average 40nm, purification process using acid washing purification. At present, the product is under development and can provide experimental samples. The first generation product of this slurry adopts high pressure resistant dispersant, which can ensure that the slurry does not have side reactions at 4.4V. The second generation of products based on the first generation of products based on the addition of film-forming stabilizers, can ensure the stability of the surface performance of the positive electrode material CEI film, and thus improve the stability of lithium-ion batteries under high power conditions. Compared with the traditional carbon nanotube slurry, this product can be used under the condition of 4.4V high voltage. Compared with the traditional SUPERP, it has the advantages of less adding amount and easy dispersion under the condition of high voltage. Product Features 1. The use of high pressure resistant dispersant, can ensure the normal use of 4.4V conditions; 2. Contains stabilizing additives to make the material preferentially film at high voltage and make the cycle more stable; 3. Apply high charge-discharge rate, strong polarization conditions to improve the electrochemical performance of lithium-ion batteries. product morphology Technical parameters Use recommendations It is recommended to use high-power NCM system, high-power LCO system, energy-type high-voltage LCO system, and high-voltage lithium-rich manganese-based system. Packing method Available in 25kg, 200kg or 1000kg packages.

Product Classification:

Share

Details

Product Introduction

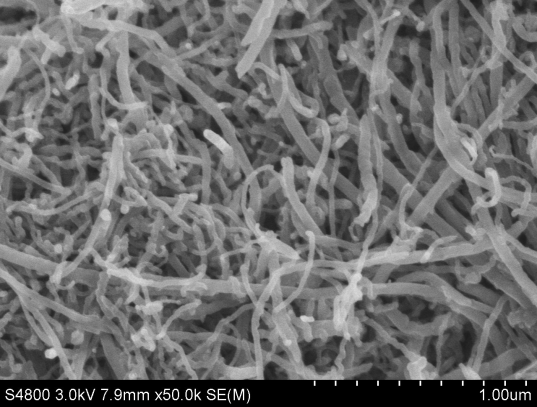

NNL-HV3 is easy to disperse carbon nanotubes as the main material, NMP as solvent. The product uses easily dispersed carbon nanotubes, diameter 10-70nm, average 40nm, purification process using acid washing purification. At present, the product is under development and can provide experimental samples. The first generation product of this slurry adopts high pressure resistant dispersant, which can ensure that the slurry does not have side reactions at 4.4V. The second generation of products based on the first generation of products based on the addition of film-forming stabilizers, can ensure the stability of the surface performance of the positive electrode material CEI film, and thus improve the stability of lithium-ion batteries under high power conditions. Compared with the traditional carbon nanotube slurry, this product can be used under the condition of 4.4V high voltage. Compared with the traditional SUPERP, it has the advantages of less adding amount and easy dispersion under the condition of high voltage.

Product Features

1. The use of high pressure resistant dispersant, can ensure the normal use of 4.4V conditions;

2. Contains stabilizing additives to make the material preferentially film at high voltage and make the cycle more stable;

3. Apply high charge-discharge rate, strong polarization conditions to improve the electrochemical performance of lithium-ion batteries.

product morphology

Technical parameters

Use recommendations

It is recommended to use high-power NCM system, high-power LCO system, energy-type high-voltage LCO system, and high-voltage lithium-rich manganese-based system.

Packing method

Available in 25kg, 200kg or 1000kg packages.

Related Products

Related Products

Message consultation