New process uses CO to produce high-quality graphene at lower cost and faster production

Release time:

May 30,2022

Russian researchers have proposed the first graphene synthesis technology using carbon monoxide as a carbon source. This is a fast and cheap method for producing high-quality graphene. The equipment is relatively simple and can be used in electronic circuits, gas sensors, optics and other fields. The research was conducted by scientists from Skolkovo Science and Technology (Skoltech), Moscow Institute of Physics and Technology (MIPT), Institute of Solid State Physics of the Russian Academy of Sciences, Aalto University and other institutions. The research has been published in the prestigious journal Advanced Science. Chemical vapor deposition (CVD) is the standard technique for synthesizing graphene, which is a honeycomb-arranged single-atom-thick sheet of carbon atoms with unparalleled performance and can be used in electronic applications. CVD generally involves the separation of carbon atoms from gas molecules and their deposition in a monomolecular layer on a substrate in a vacuum chamber. Copper is a commonly used substrate, and the gases used have been hydrocarbons: methane, propane, acetylene, spirits, etc. "The idea of synthesizing graphene from carbon monoxide came up a long time ago, because carbon monoxide is one of the most convenient carbon sources for growing single-walled carbon nanotubes. We have nearly 20 years experience working with carbon monoxide. However, the first experiments with graphene were not successful, and it took us a long time to understand how to control the nucleation and growth of graphene. The beauty of carbon monoxide is the complete catalytic decomposition, which allows us to achieve self-limiting synthesis of single-layer graphene large crystals under ambient pressure." Skoltech Professor Albert Nasibulin, the study's lead researcher, said. "This project is one of the outstanding examples of how basic research can benefit applied technology. As the understanding of the deep-level kinetic mechanism of graphene formation and growth is verified both theoretically and experimentally, optimal conditions for the formation of large graphene crystals become feasible," emphasizes Krasnikov Dmitry, a co-author of the paper and a senior research scientist in Skoltech. The new approach benefits from the so-called self-limiting principle. At high temperatures, when carbon monoxide molecules approach the copper matrix, they tend to decompose into carbon atoms and oxygen atoms. However, once the first layer of crystalline carbon is deposited and separates the gas from the substrate, this tendency subsides, so this process naturally favors the formation of a monolayer. Methane-based CVD can also operate in a self-limiting manner, but to a lesser extent. Grebenko Artem of Skoltech, the first author of the research paper, said, "The system we used has many advantages: the resulting graphene is purer, grows faster and forms better crystals. In addition, by completely excluding hydrogen and other explosive gases from the production process, this improvement can prevent accidents." The fact that this method eliminates the risk of combustion means that no vacuum is required. The equipment works at standard pressure, making it much simpler than traditional CVD equipment. The simplified design in turn leads to faster synthesis. Grebenko said: "From taking a piece of bare copper to pulling out graphene, it only takes 30 minutes." Since the vacuum is no longer required, the equipment not only works faster, but also becomes cheaper. The researchers emphasize that "once you give up the high-end hardware that produces ultra-high vacuum, you can actually assemble our 'garage solvation' for no more than $1000." The researchers also emphasize the high quality of the final material: "Whenever a new graphene synthesis technique is proposed, researchers must prove that it produces the effects they claim. After rigorous testing, we can confidently say that we are indeed high-grade graphene, which can compete with materials produced by CVD from other gases. The resulting material is crystalline, pure, and can be large enough for electronics.

Russian researchers have proposed the first graphene synthesis technology using carbon monoxide as a carbon source. This is a fast and cheap method for producing high-quality graphene. The equipment is relatively simple and can be used in electronic circuits, gas sensors, optics and other fields. The research was conducted by scientists from Skolkovo Science and Technology (Skoltech), Moscow Institute of Physics and Technology (MIPT), Institute of Solid State Physics of the Russian Academy of Sciences, Aalto University and other institutions. The research has been published in the prestigious journal Advanced Science.

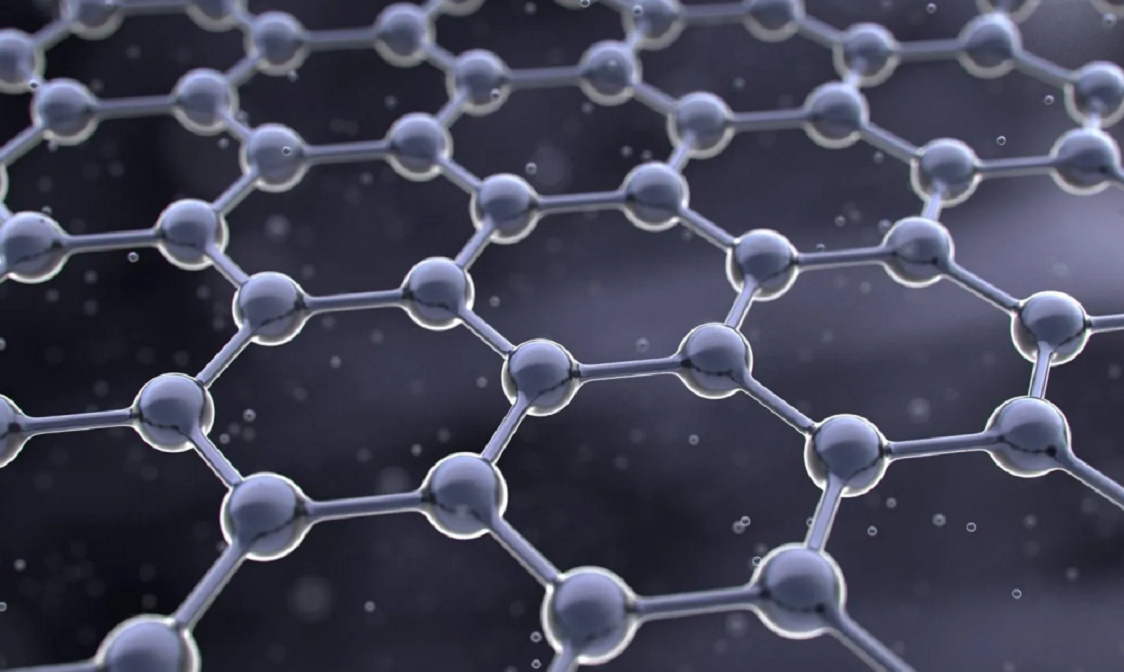

Chemical vapor deposition (CVD) is the standard technique for synthesizing graphene, which is a honeycomb-arranged single-atom-thick sheet of carbon atoms with unparalleled performance and can be used in electronic applications. CVD generally involves the separation of carbon atoms from gas molecules and their deposition in a monomolecular layer on a substrate in a vacuum chamber. Copper is a commonly used substrate, and the gases used have been hydrocarbons: methane, propane, acetylene, spirits, etc. "The idea of synthesizing graphene from carbon monoxide came up a long time ago, because carbon monoxide is one of the most convenient carbon sources for growing single-walled carbon nanotubes. We have nearly 20 years experience working with carbon monoxide. However, the first experiments with graphene were not successful, and it took us a long time to understand how to control the nucleation and growth of graphene. The beauty of carbon monoxide is the complete catalytic decomposition, which allows us to achieve self-limiting synthesis of single-layer graphene large crystals under ambient pressure." Skoltech Professor Albert Nasibulin, the study's lead researcher, said.

"This project is one of the outstanding examples of how basic research can benefit applied technology. As the understanding of the deep-level kinetic mechanism of graphene formation and growth is verified both theoretically and experimentally, optimal conditions for the formation of large graphene crystals become feasible," emphasizes Krasnikov Dmitry, a co-author of the paper and a senior research scientist in Skoltech.

The new approach benefits from the so-called self-limiting principle. At high temperatures, when carbon monoxide molecules approach the copper matrix, they tend to decompose into carbon atoms and oxygen atoms. However, once the first layer of crystalline carbon is deposited and separates the gas from the substrate, this tendency subsides, so this process naturally favors the formation of a monolayer. Methane-based CVD can also operate in a self-limiting manner, but to a lesser extent.

Grebenko Artem of Skoltech, the first author of the research paper, said, "The system we used has many advantages: the resulting graphene is purer, grows faster and forms better crystals. In addition, by completely excluding hydrogen and other explosive gases from the production process, this improvement can prevent accidents."

The fact that this method eliminates the risk of combustion means that no vacuum is required. The equipment works at standard pressure, making it much simpler than traditional CVD equipment. The simplified design in turn leads to faster synthesis. Grebenko said: "From taking a piece of bare copper to pulling out graphene, it only takes 30 minutes."

Since the vacuum is no longer required, the equipment not only works faster, but also becomes cheaper. The researchers emphasize that "once you give up the high-end hardware that produces ultra-high vacuum, you can actually assemble our 'garage solvation' for no more than $1000."

The researchers also emphasize the high quality of the final material: "Whenever a new graphene synthesis technique is proposed, researchers must prove that it produces the effects they claim. After rigorous testing, we can confidently say that we are indeed high-grade graphene, which can compete with materials produced by CVD from other gases. The resulting material is crystalline, pure, and can be large enough for electronics.

Related News